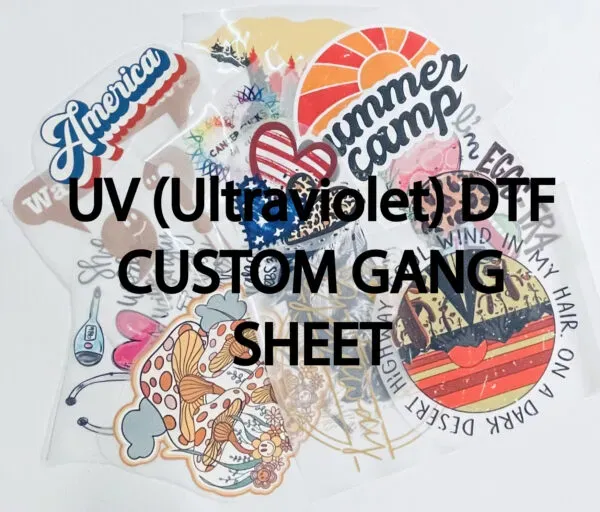

Introducing **UV DTF gangheet**, the cutting-edge advance in custom apparel printing that is transforming the way unique designs come to life. This innovative printing technology harnesses the power of Direct-to-Film (DTF) techniques combined with UV capabilities, offering high-quality prints that deliver vibrant colors and intricate details. As the demand for customized apparel continues to rise, UV DTF gang sheets make it easier for businesses and creative individuals to produce exceptional designs with greater efficiency and less waste. In this fast-evolving market, apparel design innovation is vital, and UV DTF stands at the forefront, promising to redefine quality expectations. Join us as we explore the exciting implications of this groundbreaking printing method for the future of the apparel industry.

In recent years, the landscape of apparel design has embraced various printing technologies, with **UV DTF gang sheets** emerging as a leading solution for high-quality custom garment production. This technique, which integrates Direct-to-Film (DTF) printing with ultraviolet printing methods, enables designers to create eye-catching apparel with remarkable detail and durability. By utilizing gang sheets, creators can efficiently print multiple designs on a single transfer, reducing waste and cost while enhancing productivity. As the industry progresses, the combination of these innovative printing approaches presents remarkable opportunities for branded merchandise and personalized clothing. This article delves into the significant developments in this domain, highlighting how UV DTF technology is redefining custom apparel printing.

Understanding the Foundations of Custom Apparel Printing

The world of custom apparel printing has evolved significantly over the past few years, with new technologies emerging to transform the landscape. At the heart of this evolution lies the understanding of various printing methods, notably Direct-to-Film (DTF) printing. This technique allows for vibrant and detailed designs to be transferred onto textiles, giving rise to a new era of creativity and customization in apparel. DTF technology stands out for its capability to handle a wide range of fabrics, from cotton to blends, making it a versatile choice for designers and businesses alike.

In the realm of custom apparel, businesses continuously seek innovative ways to meet consumer demands for quality and individuality. This has led to the integration of various technologies, such as UV printing, which enhances the durability and vibrancy of prints. Understanding these foundational aspects of printing technology is essential for anyone looking to create unique apparel designs that resonate with customers and stand out in a competitive market.

The Advantages of UV DTF Gang Sheets in Apparel

UV DTF gang sheets offer a plethora of advantages, making them an attractive option for businesses engaged in custom apparel printing. One of the primary benefits of using gang sheets is the efficiency it brings to the production process. By allowing multiple designs to be printed on a single sheet, businesses can save significant time and resources. This method not only reduces material waste but also streamlines workflows, enabling quicker turnaround times for orders.

Additionally, the quality of prints produced through UV DTF gang sheets is remarkable. The combination of UV curing with DTF technology results in incredibly vivid colors and sharp details that truly bring designs to life. For designers looking to make a statement with their creations, this technology provides the platform needed to showcase intricate graphics and bold visuals that can withstand the rigors of everyday wear.

Recent Innovations in UV DTF Printing Technology

Recent innovations in UV DTF printing technology have made significant impacts across various industries, particularly in the custom apparel sector. Companies like Snuggle have pioneered platforms that streamline the production process, allowing for more efficient order fulfillment and greater design flexibility. The emergence of high-capacity printers has also played a vital role, enabling businesses to meet the increasing demand for unique apparel without compromising on quality or speed.

Furthermore, advancements in ink formulations and curing processes have enhanced the capabilities of UV DTF printing. These innovations not only improve adhesion and durability of prints but also expand the range of substrates that can be used, from fabrics to a variety of other materials. This adaptability positions UV DTF printing as a formidable contender in the realm of custom apparel and beyond, catering to an array of creative possibilities.

Comparing UV DTF with Other Printing Techniques

When comparing UV DTF printing to other traditional methods, such as screen printing and sublimation, several key differentiators emerge. While screen printing is renowned for its vivid colors and long-lasting results, it can be limited by the complexity of designs and fabric types. In contrast, UV DTF technology accommodates a wider variety of materials and allows for intricate designs, making it a preferred choice among modern apparel designers.

Sublimation, on the other hand, works best with polymer-coated fabrics and is less effective on cotton. However, UV DTF proficiently handles both cotton and synthetic materials, offering greater flexibility for designers looking to explore diverse clothing lines. This versatility coupled with the high-quality prints achievable through UV DTF technology positions it as a leading choice for custom apparel manufacturers aiming to bring unique visions to life.

Cost-Effectiveness and Sustainability of UV DTF Gang Sheets

The financial advantages of employing UV DTF gang sheets in custom apparel production cannot be overlooked. Printing multiple designs on a single transfer sheet significantly reduces ink consumption and operational costs. This efficiency not only benefits producers by lowering overheads but also translates to cost savings for consumers, making high-quality custom apparel more accessible. As the demand for personalized apparel grows, the affordability provided by DTF gang sheets positions businesses to better respond to market needs.

Moreover, the environmental impact of using gang sheets aligns with sustainable printing practices. By minimizing material waste and optimizing ink usage, businesses can perform their production processes more responsibly. In a time when consumers are increasingly making eco-conscious choices, embracing technologies that offer cost-effectiveness alongside sustainability can enhance a brand’s image and attractiveness in the marketplace.

Future Directions for Custom Apparel and Printing Technologies

Looking ahead, the future of custom apparel is poised for significant transformation driven by innovations in printing technologies like UV DTF. As businesses increasingly adopt state-of-the-art methods, the demand for personalized and high-quality apparel will continue to rise. This ongoing evolution will foster a competitive landscape where creativity and technology converge, enabling both established brands and newcomers to flourish.

Moreover, as printing technologies evolve, we can anticipate further advancements that will expand the possibilities for custom apparel design. Enhanced automation in production, coupled with sophisticated design software, could usher in a new wave of interactivity and personalization options for consumers. By staying on top of these trends and adopting new technologies, businesses will be well-positioned to capture the ever-growing appetite for unique and high-impact apparel.

Frequently Asked Questions

What is UV DTF Gangheet and how does it work?

UV DTF Gangheet is a printing technology that combines UV printing with Direct-to-Film (DTF) printing methods. This process involves printing multiple designs onto a single film transfer sheet, known as a gang sheet, utilizing UV light to cure the ink quickly. This results in high-quality prints with vibrant colors and fine details, ideal for custom apparel.

What are the advantages of using UV DTF Gangheet for custom apparel printing?

Using UV DTF Gangheet offers several advantages, including superior print quality and durability, cost effectiveness through efficient use of materials, and versatility in design options. This technology allows for intricate designs to be printed on various fabric types, making it perfect for custom apparel innovation.

How do UV DTF Gangheet prints compare to traditional printing methods?

UV DTF Gangheet prints stand out against traditional printing methods like screen printing and sublimation due to their vibrant colors, ability to print on a variety of fabrics, and the use of gang sheets which maximize production efficiency. This results in faster turnaround times and lower costs for businesses.

Can UV DTF Gangheet be used for all types of fabrics?

Yes, UV DTF Gangheet technology is highly versatile and can effectively print on various fabrics, including cotton, polyester, and blends. This capability allows creators to explore diverse custom apparel designs without compromising on quality or durability.

What recent innovations are driving the popularity of UV DTF Gangheet in the apparel industry?

Recent innovations in UV DTF Gangheet technology, such as the integration of large-format printers and rapid production capabilities, have significantly boosted its popularity. Platforms like Snuggle DTF have revolutionized commercial print-on-demand services, enabling businesses to offer diverse design options efficiently and effectively.

Is UV DTF Gangheet printing environmentally friendly?

Yes, UV DTF Gangheet printing is considered environmentally friendly because it minimizes material waste by printing multiple designs on a single film transfer (gang sheet). Moreover, this technology uses less ink and energy compared to traditional printing methods, making it a sustainable choice for custom apparel production.

| Key Point | Details |

|---|---|

| Introduction to UV DTF Gangheets | UV DTF gang sheets represent a significant advancement in custom apparel printing, enhancing quality and efficiency. |

| Definition of Gang Sheets | Gang sheets allow printing multiple designs on one film transfer sheet, minimizing waste and enhancing efficiency. |

| Industry Innovations | Platforms like Snuggle DTF streamline print-on-demand services, facilitating higher volume production with minimal setup. |

| Production Expansion | Companies like EazyDTF invest in large-format printers to meet urgent custom apparel demands with quick turnaround. |

| Comparison with Other Technologies | DTF outshines sublimation for its versatility across fabric types, allowing for diverse design explorations. |

| Emerging Technologies | Integration of UV printing technologies enhances the possibilities for detailed, high-quality prints on various surfaces. |

| Benefits of UV DTF Gang Sheets | Advantages include high print quality, cost-effectiveness, design versatility, and rapid production capabilities. |

| Case Study of Snuggle DTF | Snuggle DTF’s gang sheet model enhances design diversity for resellers, promoting creativity and profitability. |

Summary

UV DTF Gangheet technology stands at the forefront of high-quality custom apparel, transforming how designs are conceived and produced. This innovative method navigates the intricacies of printing, allowing creators and businesses alike to produce vibrant, durable garments that cater to the modern consumer’s demands for uniqueness and quality. With continued advancements and industry adoption, UV DTF Gangheet has been pivotal in enhancing productivity while minimizing waste, signaling a bright future in the custom apparel landscape.